How to Select the Right Vacuum Angle Valve and Vacuum Chamber Manufacturer

In industries where precision, efficiency, and durability are non-negotiable, choosing the right vacuum angle valve and the most reliable vacuum chamber manufacturer can make a significant difference. Whether you’re working in research laboratories, semiconductor production, or advanced manufacturing, the quality of your vacuum systems starts with sourcing the best vacuum angle valve and collaborating with a trusted vacuum chamber manufacturer.

A vacuum angle valve is a critical component in any vacuum system because it controls the flow of gases and maintains the necessary pressure conditions inside the chamber. Selecting the right valve ensures the system’s efficiency, protects sensitive equipment, and contributes to the safety and longevity of operations. For this reason, understanding how these valves function and what to look for when buying them is essential for anyone dealing with vacuum technology.

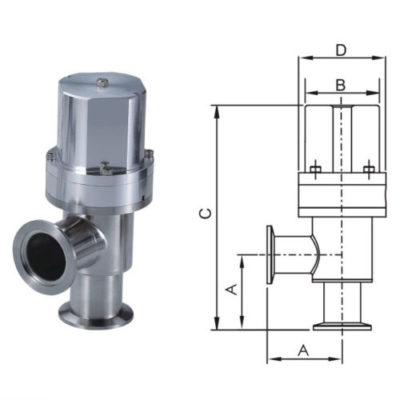

A vacuum angle valve is typically designed to withstand high or ultra-high vacuum environments. Its angular structure makes it easy to install where space is limited, and the design minimizes dead space, which is important for maintaining clean and controlled processes. These valves often come in manual, pneumatic, or motorized versions, depending on the level of automation required. The choice between them depends on the specific application, the frequency of use, and the operating environment.

Equally important is selecting a vacuum chamber manufacturer that can deliver high-quality chambers built to exact specifications. These chambers are the heart of many critical applications, from space simulation to thin film deposition and material testing. A reliable vacuum chamber manufacturer understands that each project may demand custom sizes, materials, and design features. They should have a proven track record, a robust quality control process, and the ability to adapt to evolving technological needs.

One of the main factors to consider when purchasing a vacuum angle valve is the material used. Stainless steel is a common choice due to its excellent durability, corrosion resistance, and ease of cleaning. For ultra-high vacuum applications, valves must be carefully designed to prevent leaks and withstand repeated cycles without compromising performance. The seals used in these valves, whether metal or elastomer, must be chosen based on the specific process conditions, including temperature and chemical compatibility.

Another aspect worth paying attention to is maintenance and serviceability. A high-quality vacuum angle valve should be easy to maintain, with replaceable parts and clear documentation. Downtime can be costly in industries relying on vacuum systems, so valves that are easy to service help prevent disruptions and maintain operational efficiency.

Partnering with the right vacuum chamber manufacturer is just as crucial. An experienced manufacturer will not only provide standard chamber designs but also offer customization options to meet unique research or industrial requirements. They often work closely with clients during the design phase, ensuring that factors such as material selection, chamber geometry, and integration with other vacuum components like pumps, gauges, and valves are optimized for performance.

When sourcing these products, it is vital to ensure that the manufacturer adheres to international quality standards. Certifications, testing procedures, and customer support should all be part of the decision-making process. A reputable manufacturer will willingly share information about their quality assurance practices, material sourcing, and production capabilities.

The investment in a reliable vacuum angle valve and chamber system pays off in the long run. High-quality valves reduce the risk of leaks, contamination, and system failure, while well-built chambers offer the stability and durability needed for repeated use. Together, they help maintain the integrity of experiments and production processes, whether they involve delicate scientific research or large-scale manufacturing.

vacuumchamber.com is a trusted platform for professionals seeking durable, precision-engineered vacuum equipment that meets the demanding standards of modern industry. When you choose suppliers through them, you gain access to a network of experts who understand the complexities of vacuum systems and can recommend the best solutions for your specific needs.

It’s also wise to think about future requirements. Technology is constantly advancing, and your vacuum system should be adaptable enough to handle new processes and innovations. This means working with suppliers who offer not just products but also ongoing technical support, replacement parts, and upgrade options.

At the end of the day, choosing the right vacuum angle valve and vacuum chamber manufacturer is about more than just technical specifications — it’s about building a foundation for successful, efficient, and safe operations. By investing the time to understand your options and partnering with reputable experts in the field, you can be confident that your vacuum systems will deliver the performance you need, now and in the future.

vacuumchamber.com makes it simple to find products and partners you can rely on, empowering you to focus on what truly matters — driving your research, production, and innovation forward with absolute precision.

For more info:-

Comments

Post a Comment