Boosting Modern Vacuum Systems with Reliable Components and Practical Applications

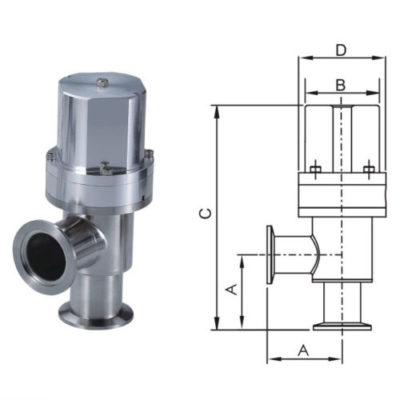

One of the most reliable parts for businesses that use controlled vacuum setups is the Vacuum Angle Valve. Its design helps keep pressure stable and stops leaks during use, which makes sure that all systems work well. This valve makes it easier to alter pressure in labs and business units, which lowers the chance of detrimental sensitive items. Industries adore it since it lasts a long time and offers reliable consequences, even if it's used for a long term. This valve is used as a safety measure in many configurations to keep gases and liquids clean and under control. Its features let teams operate without stopping.

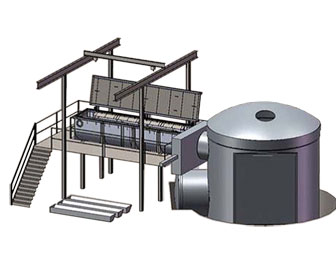

How Small Vacuum Chambers Support Precise Experiments

Small Vacuum Chambers are very important for research labs and small businesses because they give scientists and engineers a regulated space to do different tests and experiments. These chambers are small yet dependable, making them a safe place to study materials, create certain conditions, and do chemical or heat activities. They are excellent for firms or labs that need reliable contraptions however can't have enough money huge systems due to the fact they're transportable and paintings properly. The manner these chambers are made makes them correct, that is vital for purchasing the equal consequences whenever. They are still very crucial in lots of fields, from electronics to trying out for aerospace.

Combining Strong Valves and Compact Chambers for Best Output

A trustworthy valve and a chamber work together to make vacuum procedures more consistent. The valve controls the gases and pressure inside the chamber, which makes the space separate. This partnership makes processes more stable, which saves businesses time and money. Many businesses in the food packing, manufacturing, and clean energy industries now use these kinds of systems. Both instruments work well together to develop solutions for sensitive procedures that need very low vacuum levels. Together, they help industries reach certain criteria without any problems or too much upkeep.

Why Durability Matters in Vacuum Equipment

Durability is essential for vacuum gadget because it has if you want to tolerate versions in strain and normal operation. Parts like valves and chambers are made the usage of materials that do not rust or wear down, in order to paintings well for years. Companies that purchase extremely good components don't ought to deal with downtime resulting from preservation or screw ups. Reliable device also makes employees greater assured considering they realize the system will work safely. These items are useful for both big and small enterprises that need tools that last since they focus on long-term performance.

Expanding Use in Diverse Industries

Vacuum tools are no longer just for labs. They are utilized a lot in fields including health, technology, research, and even food storage. With compact chambers, it's easy to test items or keep materials safe, and valves help keep the conditions just right. These tools are growing more popular as businesses try to be more efficient because they may save space and money. They let firms function with accuracy without having to spend a lot of money on big infrastructure. This flexibility helps both new businesses and existing ones make their operations better.

Reducing Risks with Controlled Vacuum Solutions

One big purpose corporation select cutting-edge vacuum structures is safety. Valves and chambers that are designed effectively lower the probabilities of leaks, infection, or accidents as a result of excessive pressure. It is very important for agencies like drug treatments and electronics to keep their environments easy and underneath control. These devices make sure that production is going smoothly without decreasing quality. Such device is even more tempting because it saves cash via having fewer problems. Companies can also without difficulty comply with safety guidelines because the structures are made to perform within precise restrictions while maintaining both personnel and merchandise safe.

Boosting Efficiency While Cutting Costs

Companies may save time and money with reliable vacuum systems since they always get the same results. Chambers and valves are examples of device that keeps production on schedule by preventing delays resulting from technical problems. Because those components are made to last a long time, they do not want as a good deal maintenance. Businesses can store even more money on operations by the use of electricity-green designs. These systems are a good alternative for businesses that want to be more productive and expand because they provide so many benefits. Many small businesses may also afford these solutions because they take up less room and power than earlier, bulkier systems.

Conclusion

Vacuum systems are changing the way businesses function by making sure they do their jobs safely and accurately. Businesses may get solid results without spending too much or taking too many risks with sturdy parts like the Vacuum Angle Valve and flexible Small Vacuum Chambers. These technologies aren't just for labs; they're changing the way many industries work by providing small, strong, and effective solutions. As industries grow, the need for reliable equipment like this will grow since it helps get good outcomes without having to set up sophisticated systems. Visit vacuumchamber.com to learn more about reliable solutions and see what options are available that meet today's needs.

Comments

Post a Comment